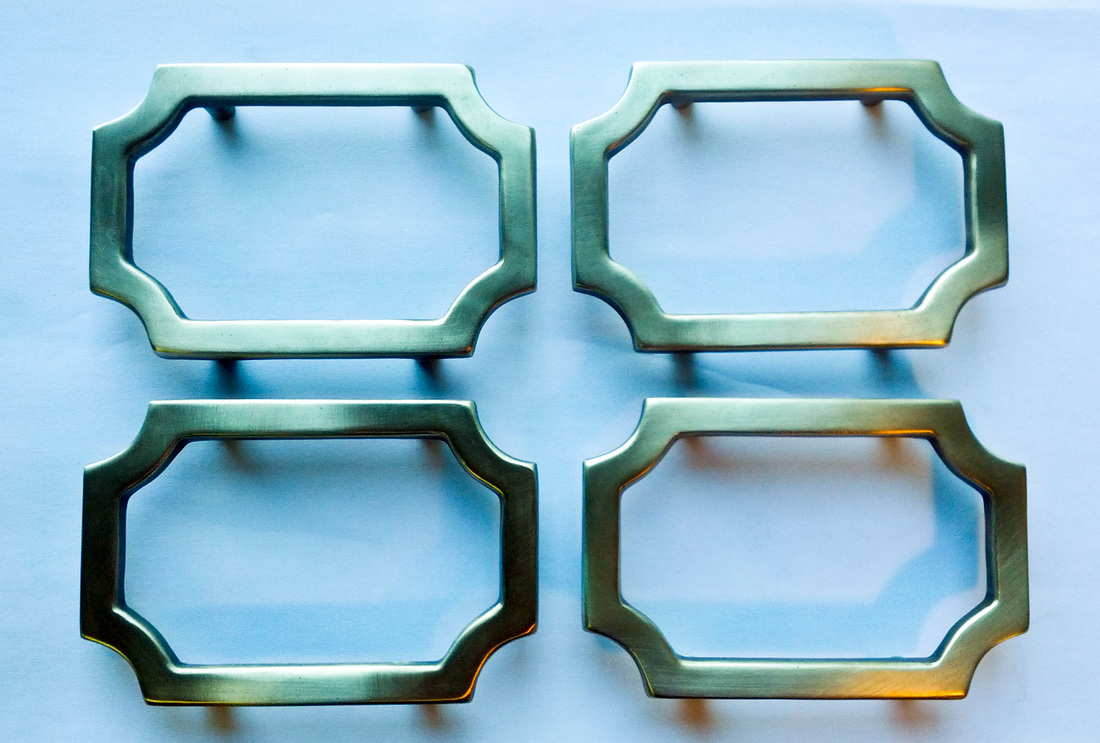

When I showed interest in foundry ideas many years ago, the local foundry owners and workers seemed all too happy to help. I was just a starving woodcarver who wanted to cast stuff. Before I knew it, I was in the foundry world, carving various objects for casting in the memorial and giftware field. Every project I brought in for casting would bounce back at me for modification. It was a long journey, learning to prepare three dimensional work for casting. Still, I was a woodcarver with two hungry kids, a guy with one small gig. It was learn or go and work at Home Depot.

I was sort of raised in the business by the original owner of Riverside Brass, right across from my studio in the late 70s. Subsequent owner/managers have been great mentor/collaborators.

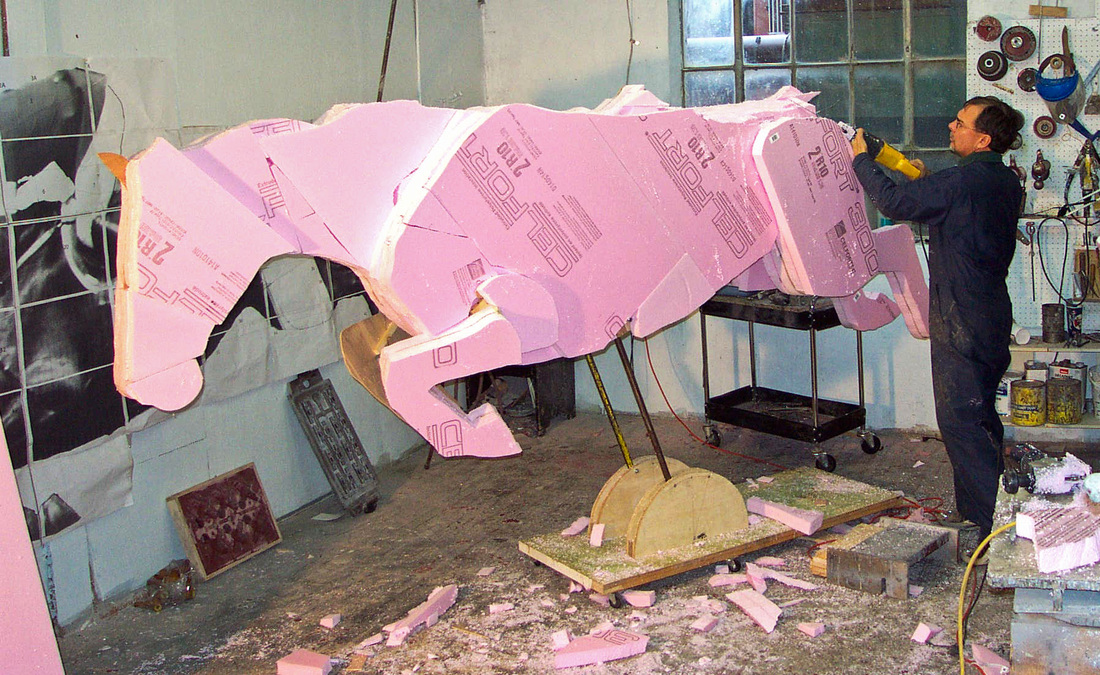

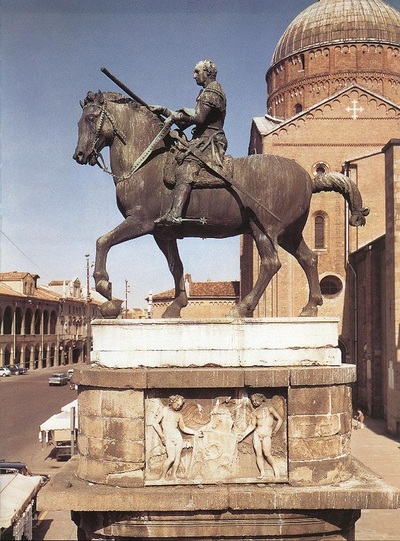

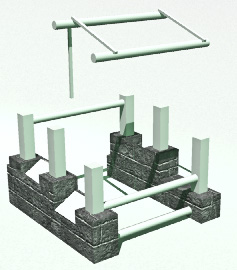

About 10 years ago I was approached by Artcast to mentor a young sculptor from St. John's Newfoundland. He had created his own project, found his own funding, and was looking for a way to cast this large piece in bronze. Artcast thought he might benefit with a little help creating the master pattern. Morgan MacDonald arrived in January and spent much of the winter in my studio.

Still, I think I've added to the creative community a little and hope to do more. There is always hope that those that follow will do things with less struggle, fewer mistakes.

RSS Feed

RSS Feed