I had a customer of long standing, Trystan, who had started doing trade shows in the US. Trystan makes 'site furniture', or outdoor amenities like benches, tree grates and fountains. I had done all their masters and tooling for cast iron and aluminum since they got started in the early 80s. They sent a thumbnail of a hare jumping over a tortoise, wondering what it would cost to get this done about 9' long in cast iron.

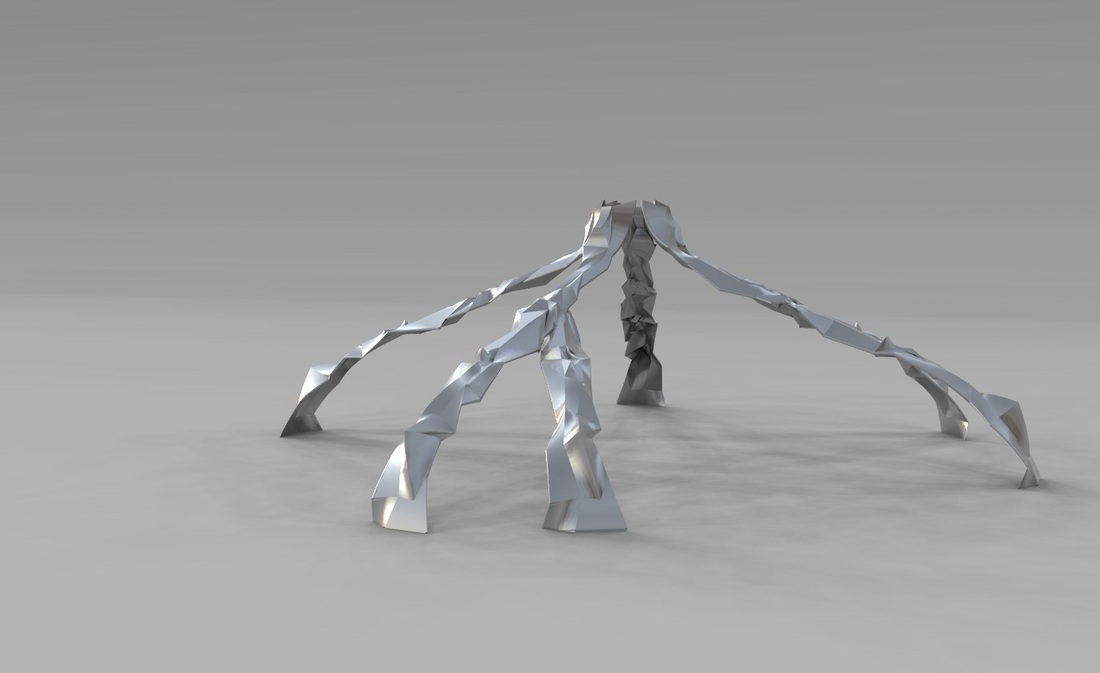

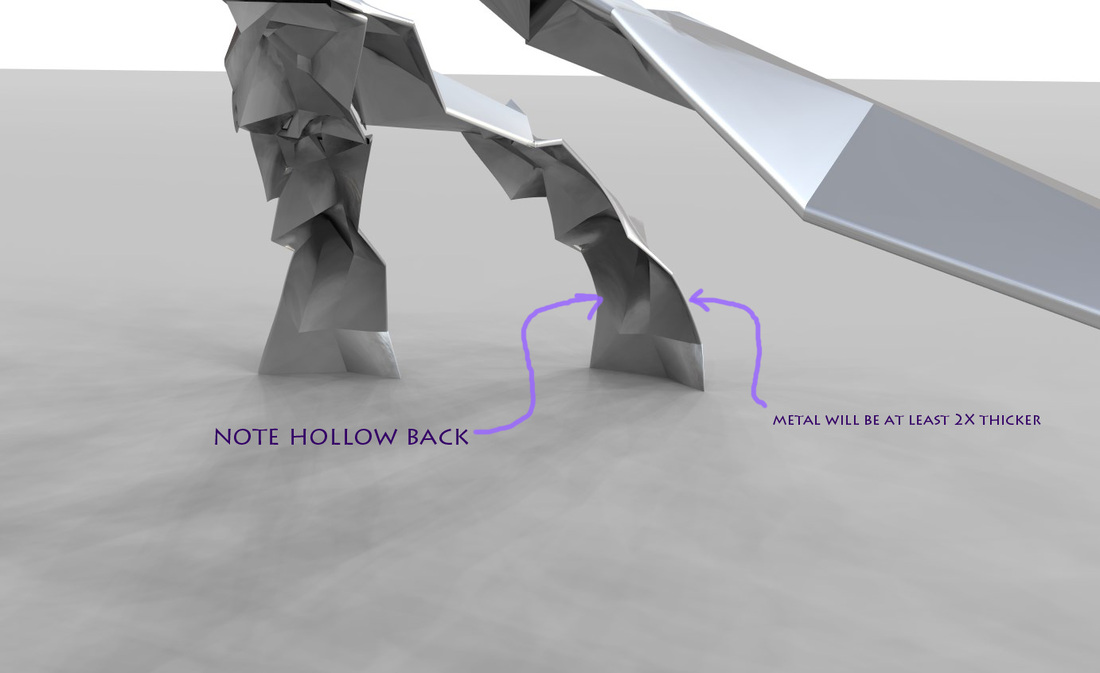

It has always been my practice to try to add value to customers' ideas. I figure that if I give away some expertise off the top that I will show that I have the chops, and that I'm happy to collaborate. I wrote this back as an aluminum casting, cutting the cost substantially, adding other ideas to make it fly. The rabbit was going to be mounted on a pole, and I was really nervous about the idea of kids jumping up and down on that long fulcrum.

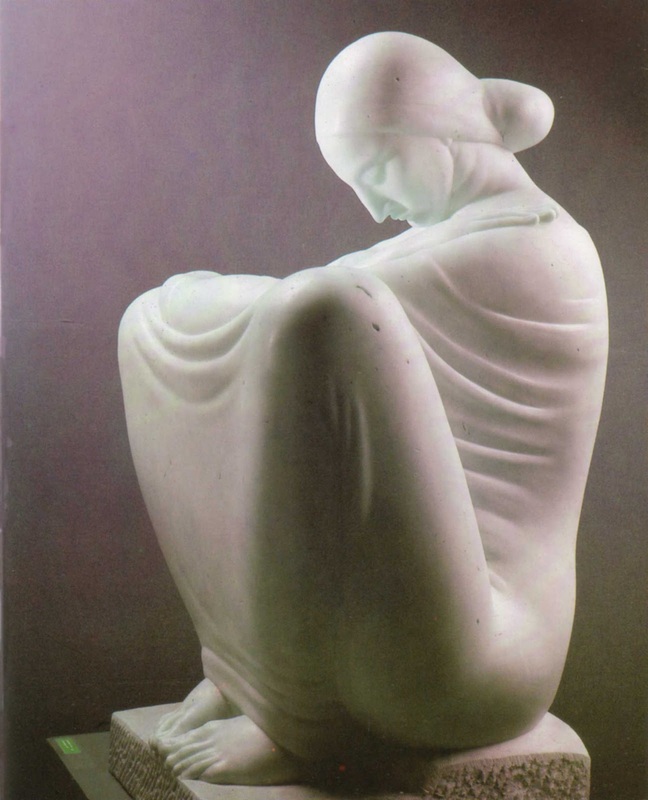

I did get the job. It was pretty exciting. Up here in the Frozen North, New York seems like a big deal. They were trusting me to do this sort of grand, sort of cartoonish project. The landscape architect for the NYC parks system sent a clay maquette, perhaps 17" wide for me to work from.

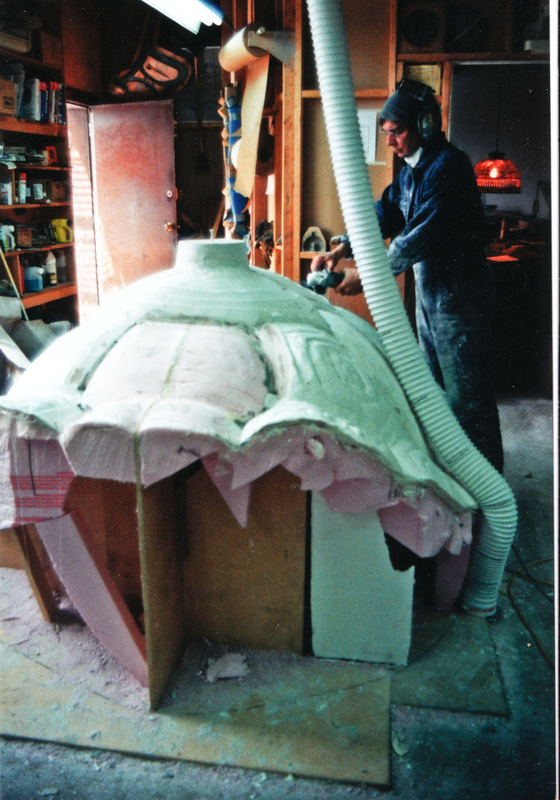

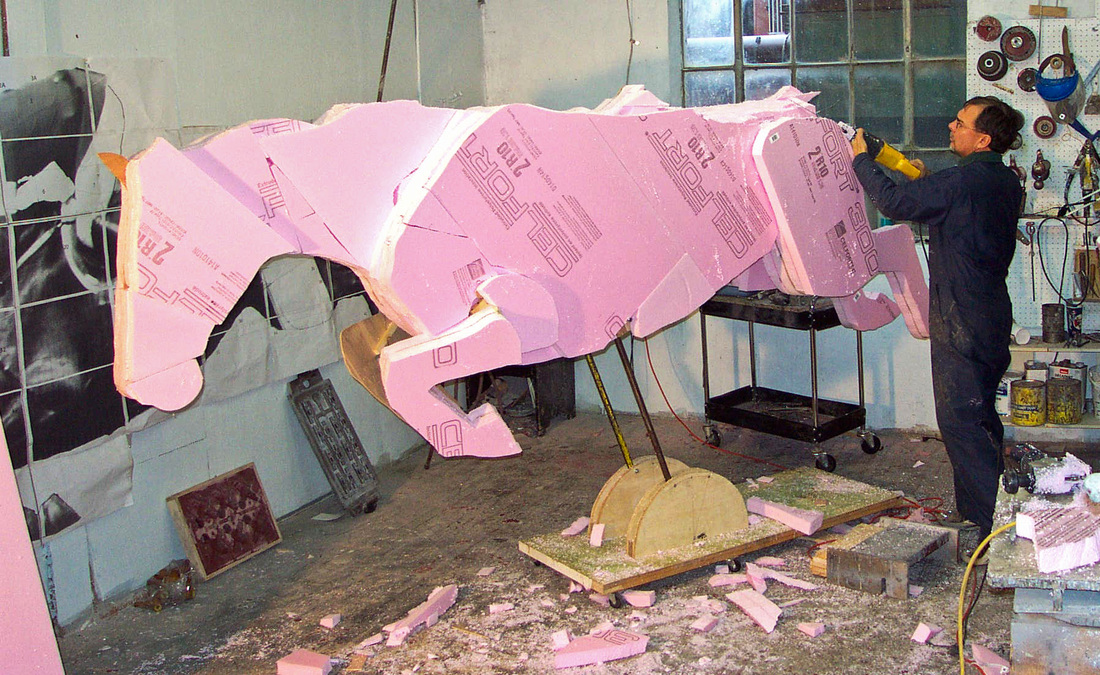

I hired an assistant. We spent untold hours building the original in styrofoam, shaping as close as possible to the final surface. I added plaster on top, making the surface smooth and even more detailed. I waxed the surface and started laying epoxy clay on top, gauged by eye to be roughly .3" (8mm) thick.

RSS Feed

RSS Feed