There have been moments in past decades, recurring moments, much like Lucy's repeated football trick on Charley Brown, where I think " ha, this is IT, I've Made It." When I got the go ahead, this was my thought.

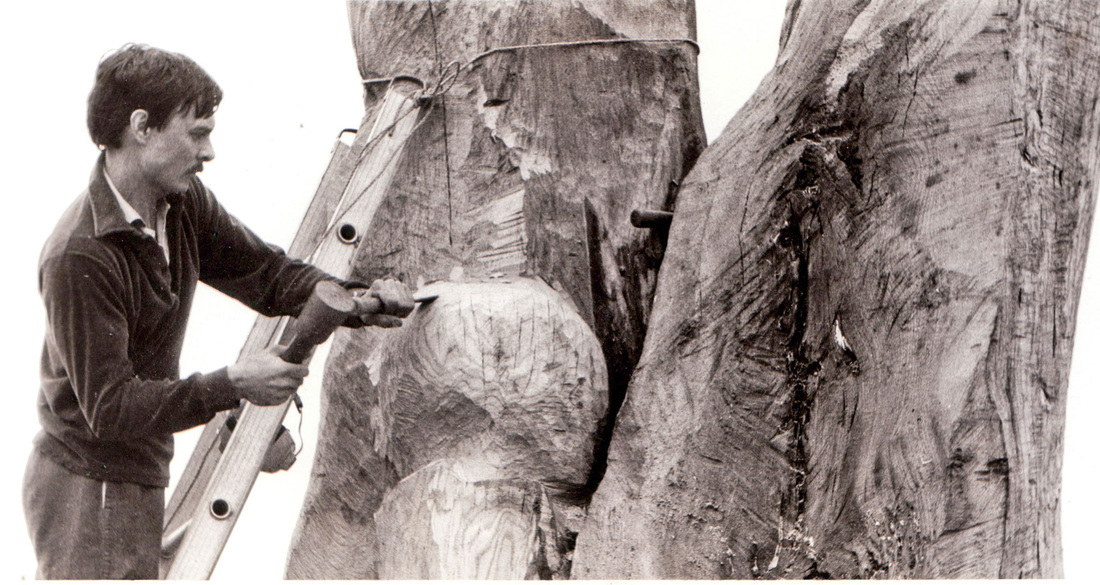

Here is the tree, lying on its side in the yard. Notice my elderly Pioneer chainsaw near the top.

I designed a base that would allow maximum airflow around the base of the scuplture. Wood will stand a long time as long as there is no lasting damp area.

When I figured I was done, they brought a big flatbed truck and crane. This is the morning when they dropped the scuplture in place.

This was installed in a field near a mall. It was visible for some distance. As I remember, it got a small mention in the local weekly paper. That was it. That big moment. Lucy pulled the football again.

Most of 30 years later, this piece still stands:

RSS Feed

RSS Feed