For some time I've been a supplier to a site called Custom Made. They supply a place for the listing of odd projects of any description. Makers like me get listed as trusted suppliers. We look at job boards and quote on work. The site takes a small percentage to handle some of the trust factor, but the whole transaction happens directly between customer and supplier.

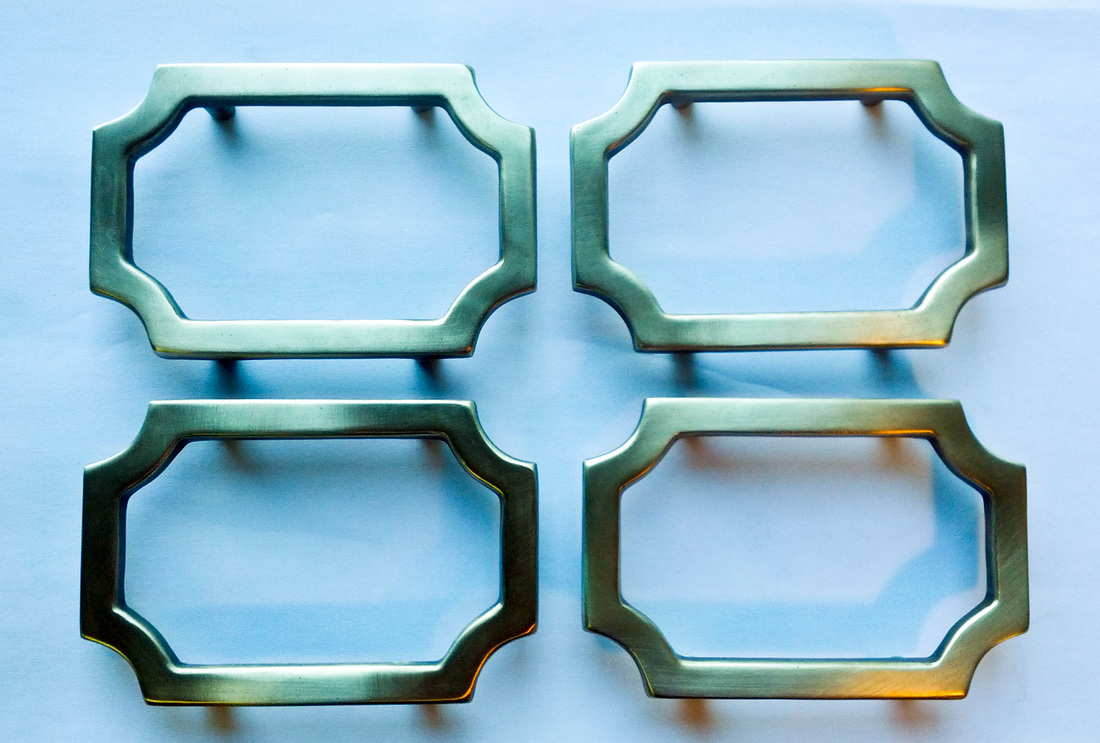

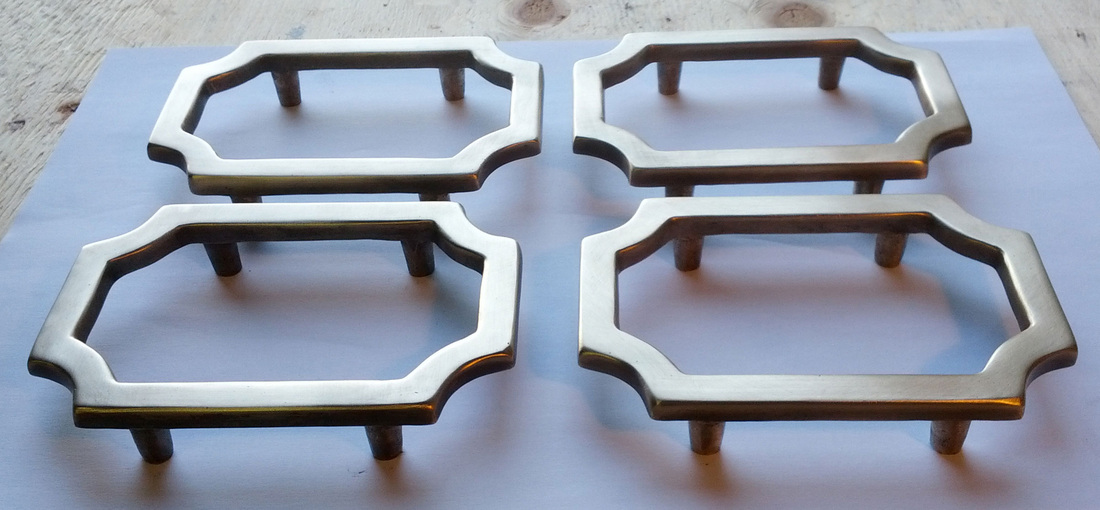

Shawn Broaddus, an interior designer and furniture designer near Atlanta, GA , wanted some custom cabinet pulls made for a credenza that she was building. She wasn't sure just what she wanted. She sent me a photo of a rough version of her project, and I sent back quick images from Rhino 3D:

..., and, whew, not all projects are this easy. Hardly a day goes by when I'm not researching some technique or gizmo to help save my bacon. Today I discovered a pretty good looking 3D printer. I've tried to avoid expensive tools, preferring to job out this work, but this is getting tempting. I wasn't that long making the master pattern for Shawn's job, but this would have reduced the work to a few minutes. Hmm, maybe I have a few minutes to spare. Perhaps I love the smell of fresh wood, and don't love the smell of burning ABS?

RSS Feed

RSS Feed