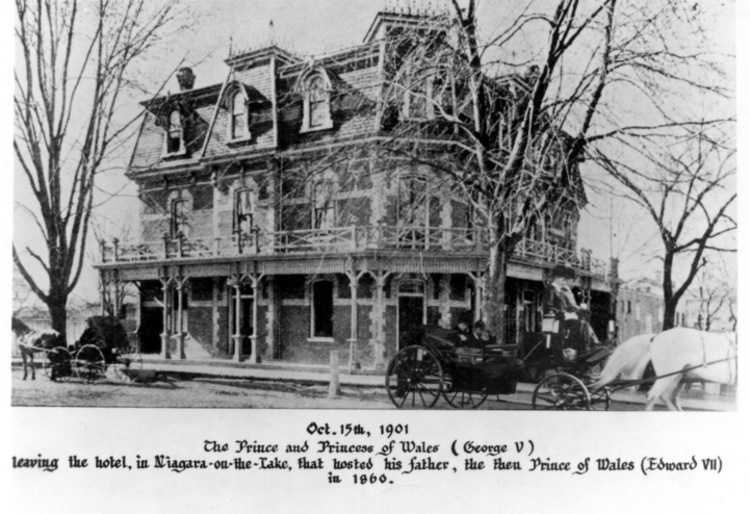

The Prince of Wales Hotel was built over 100 years ago. It has seen good days and bad. When global entrepreneur Si Wan Lai came to Niagara-on-the-Lake, the town changed. The hotel was to go from a near-relic to a rare 5 star hotel, all in less than a year. It was amazing to be part of that change.

The door pulls, though, were a serious challenge. I had to cast separate custom stand-offs that would allow these to be mounted precisely back-to-back. The mounting had to be fairly invisible, and really strong. These huge doors were solid mahogany and custom bevelled glass.

I spent many days in Niagara with the manager of Artcast, Marcus Knoespel, installing everything. I had taken two long days in my studio practising the door pull mounting, as there was no room for mistakes here.

Somehow the flooring got installed rather early, exposing the huge marquetry areas and the carpets to the tramp of many hurried feet, falling tools and the scrape of ladders. I had to install a heavy bronze sign over the reception desk shown above. The granite desk top had been installed, featuring a gorgeous red figure to the stone. It was covered with a tarp, and I did stand on it for some time, struggling to find some mounting place amid the delicate wooden tracery overhead.

It was fun being part of such a to-do, making such over-the-top finery. It's not often you get paid to do your very best work for such an extended period of time.

RSS Feed

RSS Feed